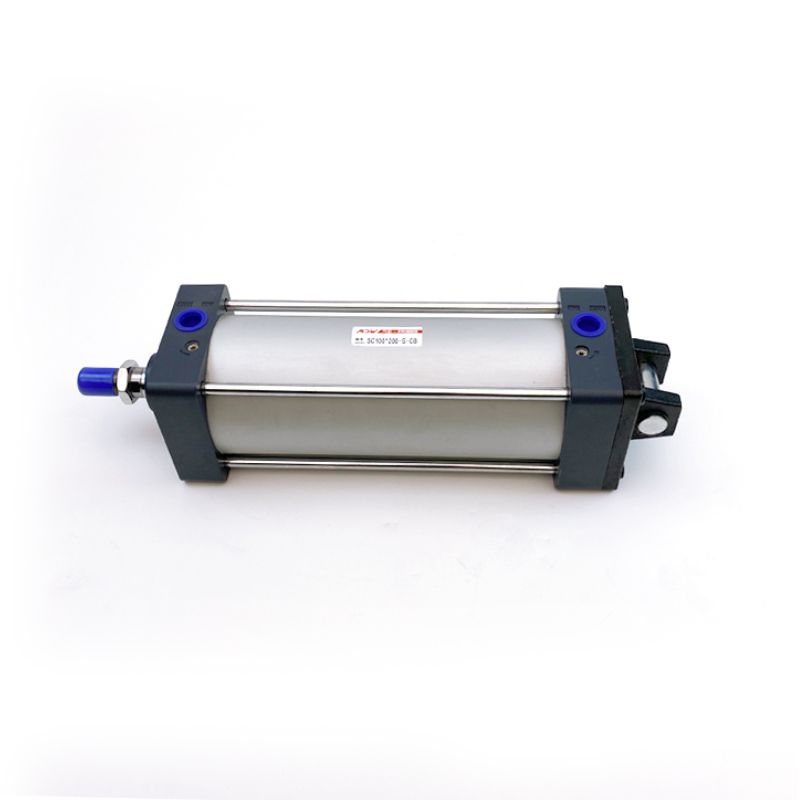

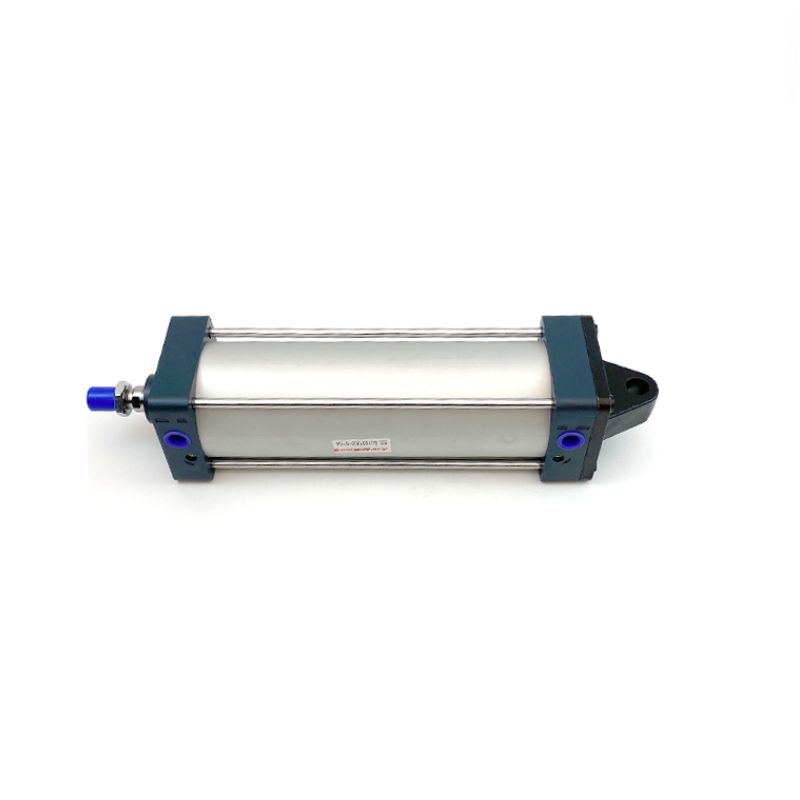

In modern industrial automation, the performance and stability of cylinders, as the core power transmission components, play a crucial role in the smooth operation of the entire system. Our well-built standard cylinders, with their compact size, excellent anti-corrosion performance and high temperature resistance, stand out in many industrial applications and become the preferred choice of the industry.

1. Compact and refined size design:

This standard cylinder has been precision engineered to pack powerful functionality into a compact size. The compact size not only means less installation space, but also reduces the overall weight of the system, making it easier to transport and install. Whether it's a space-constrained situation or the pursuit of lightweight design, this cylinder can easily meet the task.

2. Aluminium alloy cylinder barrel with excellent anti-corrosion performance:

The cylinder barrel is the core component that withstands all kinds of working conditions, and we choose high-quality aluminium alloy to manufacture it. Aluminium alloy, with its excellent anti-corrosion performance, ensures that the cylinder can maintain a long and stable working condition in various harsh environments. Whether it is humidity, salt spray or corrosive gases, aluminium alloy cylinder barrel can make the cylinder run stably and unaffected.

3. High temperature resistant sealing material:

For the high temperature challenges that cylinders often face in industrial automation, we have specially selected high temperature resistant sealing materials. This material can maintain stable sealing performance in environments as high as 150°C, effectively preventing gas leakage and ensuring the continuous and stable operation of the cylinder under high temperature conditions.

4. Thickened aluminium alloy frame, pressure and impact resistant:

The front and rear covers of the cylinder are designed with a thickened aluminium alloy frame, which is not only pressure-resistant but also has excellent impact resistance. This design ensures that there is no air leakage under high-pressure environment, which significantly extends the service life.

5. Imported seals ensure no leakage:

We use imported seals to ensure excellent sealing performance of the cylinder. These seals are wear-resistant, safe and durable, effectively preventing gas leakage and providing users with more stable and reliable power transmission solutions.

6. Precision ground piston rod, precise and durable:

The piston rod of the cylinder has been finely ground three times to ensure small stroke error and long service life. This fine grinding process makes the piston rod smoother and more accurate in movement, ensuring the overall performance and use of the cylinder.

7. High-strength column, solid and reliable:

The cylinder's column adopts a rounded mounting design, which is not only non-slip and firm, but also has high strength. This design ensures the stability of the cylinder during operation and further enhances the service life and reliability of the cylinder.